Silk Screening

Silk Printing

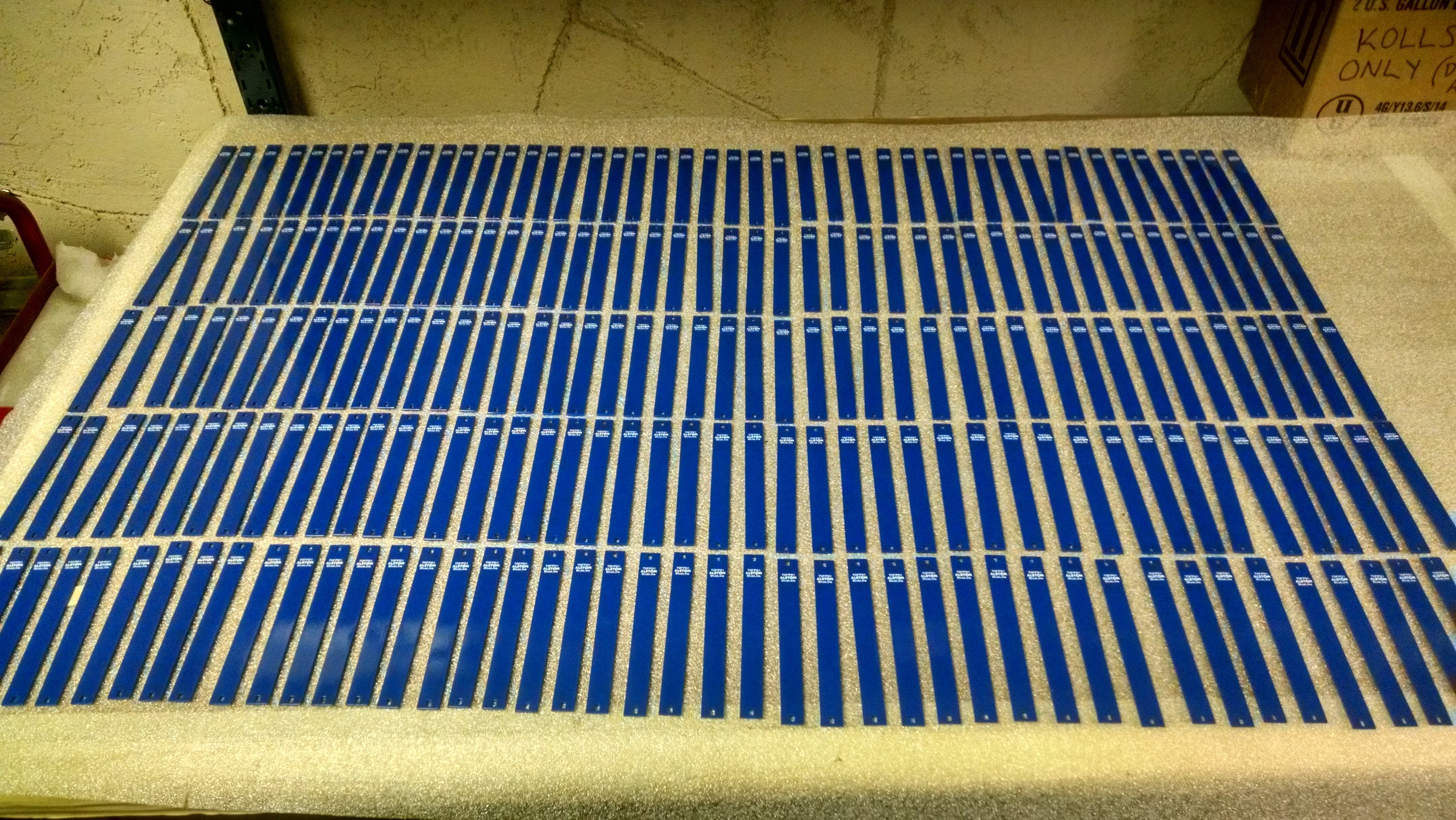

The silk screen process is one of the most versatile of printing methods. Silk screen printing can be used on fabric, metals, glass and, of course, paper and cardboard. Large commercial screen print operations now use automated equipment, but hobbyists, artists and small shops continue to do silk screening by hand.

The Process

The stencil is attached to the under side of the screen. The exact procedure depends on the type of stencil used. The material to be printed is placed on the table, and the screen is lowered over it. A generous quantity of ink is put at the top of the pattern, but outside the printing area. The squeegee pulls the ink across the pattern and forces it through the silk onto the material.

Most screen printing jobs require more than one color of ink. Each color must thoroughly dry before the next color can be applied. Large screen print operations have a different screen for each color. In a small shop, the same screen is cleaned of the stencil and ink and then reused for the next color.