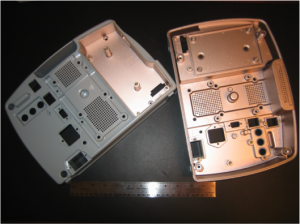

EMI Shielding

Conductive Paint is widely used in the electronics industry today for EMI RFI shielding and electrostatic discharge (ESD) control. Conductive paint is sprayed onto the plastic using an air atomizer or airless spray equipment. Key process attributes are tailored for each application to provide optimal EMI/RFI shielding or electrostatic control performance including:

Spray pattern - parts can be masked by hand with tape and plugs or by using custom built paint masking fixture

Paint type - includes graphite, nickel, copper, silver plated copper and silver particles in water or solvent based matrix.

Protecting operating theaters to shield EMI from stray or superfluous signals entering from another environment. Providing EMI Shielding vital for human organ monitoring equipment and systems.